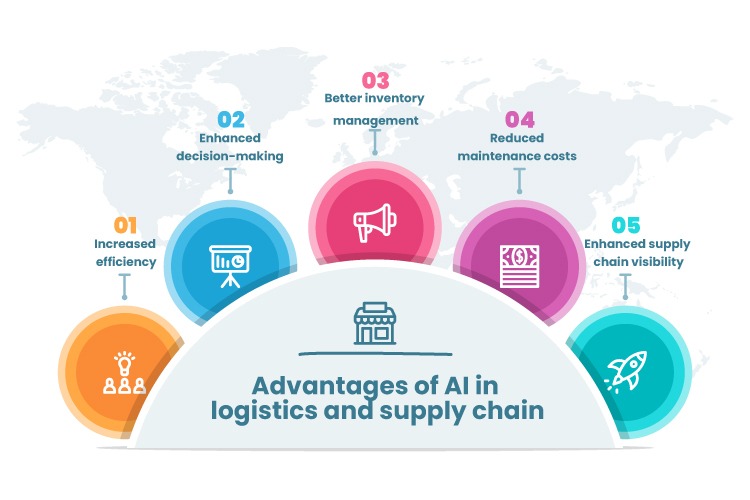

Artificial Intelligence (AI) is transforming the highly competitive logistics and supply chain sector. With its vast capabilities, AI enables companies to make smarter, data-driven decisions, leading to improved efficiency and greater operational control.

By leveraging automation, machine learning (ML), and predictive analytics, businesses can optimize supply chain operations, forecast demand with greater accuracy, and adapt to market changes swiftly. AI-driven insights help organizations stay ahead in a fast-evolving industry landscape.

Through AI-powered solutions, logistics companies can enhance productivity, reduce operational costs, and prevent supply chain disruptions. As a result, AI is not just a technological advantage — it is becoming an essential tool for building resilient, future-ready logistics networks.

The technology that once existed only in science fiction has now become essential to businesses.

Today, most people are familiar with artificial intelligence (AI), the field focused on creating machines capable of human-like thought processes.

AI involves applying computers to tasks that traditionally required human intelligence.

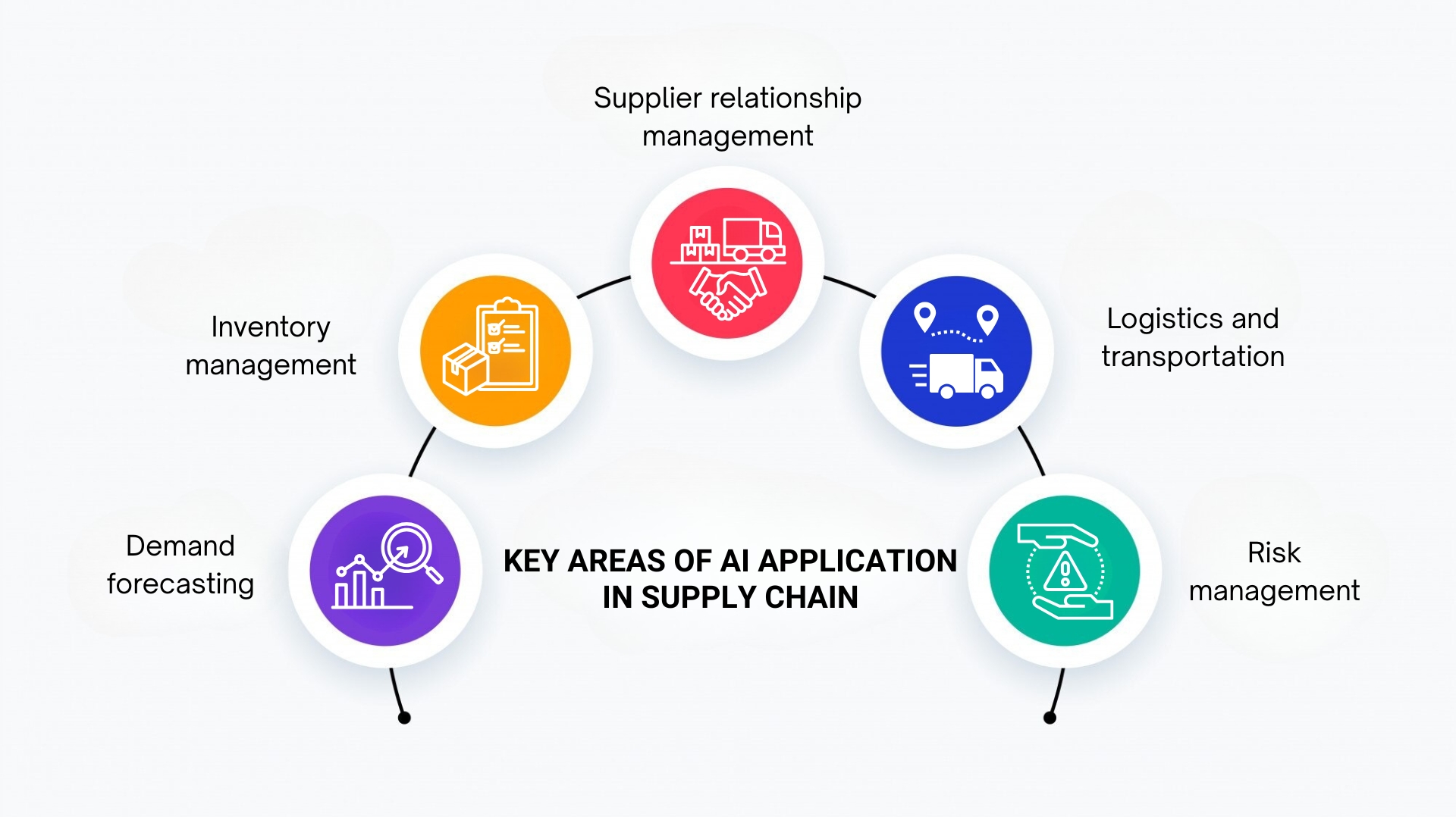

Key areas of AI application in Supply Chain

Benefits of artificial intelligence (AI) in supply Chain

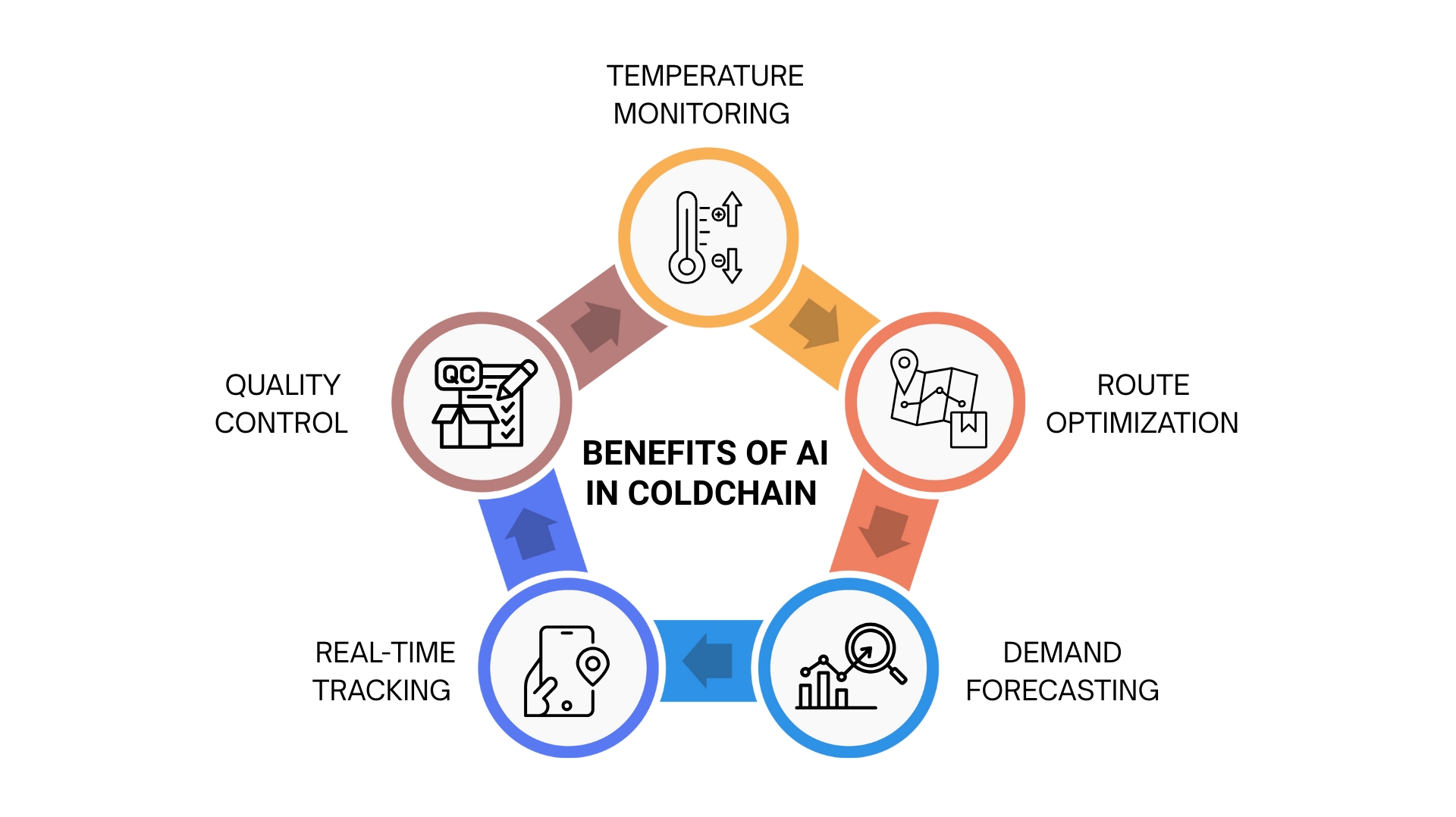

Benefits of Ai in Cold Chain

Abhi Impact Logistics, a well-known supply chain management firm in India, uses the newest technologies to improve its offerings. It makes use of AI to deliver effective services.

Demand forecasting: To precisely predict demand, AI examines past data, consumer behavior, industry trends, and other factors. This improves supply chain efficiency and lowers costs by lowering inventory expenses, preventing stock-outs, and decreasing overstock situations.

AI-powered route optimization reduces transit times, lowers transportation costs, and improves on-time delivery by optimizing delivery routes based on real-time data, including weather, traffic, and road closures.

Automation of the warehouse: Abhi Impact Logistics seamlessly manages its warehouses with AI. Our warehouse operations are streamlined by AI-powered robots and self-driving cars that automate picking, packing, and sorting. This results in better order accuracy, lower labor costs, and enhanced efficiency.

Supply chain visibility: AI is used by us to manage our supply chain. Logistics experts can follow shipments, keep an eye on inventory levels, and spot delays or bottlenecks thanks to AI's real-time supply chain visibility. This makes it possible to make preemptive decisions, manage inventories effectively, and provide better customer services

Predictive maintenance: AI evaluates sensor data from machinery and transportation vehicles to precisely forecast maintenance requirements. This lowers unscheduled downtime, improves maintenance plans, and prolongs asset life, which lowers costs and increases asset utilization.

Risk management and supplier selection: AI helps with supplier selection by analyzing data on financial stability, performance, and dependability. AI can also aid with risk reduction and contingency planning by identifying possible hazards like supply chain interruptions, geopolitical disasters, or weather-related problems.

Improved customer experience: Abhi Impact Logistics is constantly working to make their customers' experiences better. We employ AI to improve the client experience. By giving real-time information, monitoring updates, and quickly answering client questions, chatbots, virtual assistants, and personalized suggestions driven by AI improve the customer experience and increase customer happiness and loyalty